HVAF Arc 300

HVAF-Arc Twin-Wire Metalizing System

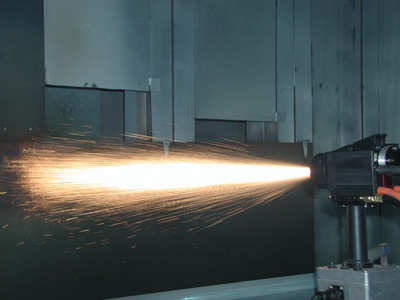

For super dense, low porosity coatings. Unlike regular arc spray systems that use compressed air, the HVAF Arc 300 utilizes a high-velocity, high-temperature jet (through combustion of air-propane mixture) for atomization. This not only provides superfine particle atomization, but also creates a reducing oxygen-free environment that envelopes particles in flight, shielding them from oxidation. This effect, combined with very high jet velocity, permits the formation of very dense, low-porosity coatings. This is the only system in the world capable of producing such coatings from wire stock.

For super dense, low porosity coatings. Unlike regular arc spray systems that use compressed air, the HVAF Arc 300 utilizes a high-velocity, high-temperature jet (through combustion of air-propane mixture) for atomization. This not only provides superfine particle atomization, but also creates a reducing oxygen-free environment that envelopes particles in flight, shielding them from oxidation. This effect, combined with very high jet velocity, permits the formation of very dense, low-porosity coatings. This is the only system in the world capable of producing such coatings from wire stock.

Advantages:

- High Density Coatings

- Low Oxide Content

- Low Porosity

Uses:

- Advanced Surface Restoration and Protection

HVAF-Arc Twin-Wire Metalizing System

The Arc Master 300 spray system's compressed air requirements are 50 SCFM at 125 PSI. The max operating current is 300 Amps. The spray system ships with a Miller power supply (450 A, 18-38 V, 174 kg weight).

The Arc Master 300 spray system's compressed air requirements are 50 SCFM at 125 PSI. The max operating current is 300 Amps. The spray system ships with a Miller power supply (450 A, 18-38 V, 174 kg weight).

In addition to compressed air, the system requires a fuel gas such as propane, propylene, natural gas, or MAPP-gas. Most commonly propane cylinders are used.

For application of materials with low melting points the spray gun can be ordered in a High Feed Rate (HFR) configuration. The following table shows the spray rates of some common materials.